CNC Plastic Machining

CNC Plastic Machining Services

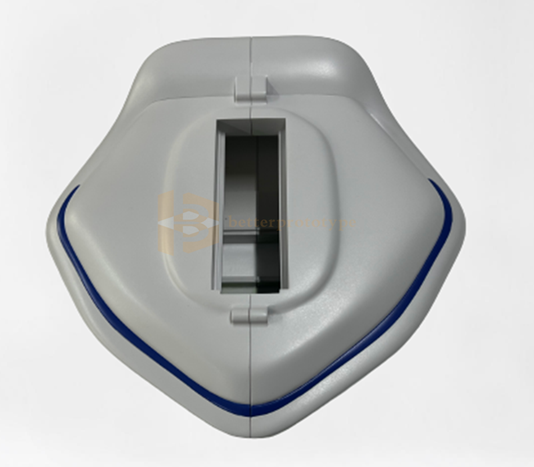

CNC plastic machining is a rapid way to make high quality plastic mechanical parts and appearance plastic models by CNC machines such as 3 axis, 4 axis and 5 axis, it comes in handy when non-printable materials are needed. With this technology, we can not only make plastic concept models and precise functional components but also provide complete solutions for the production needs of low-volume machining.

Why USE CNC Plastic Machining At BP Rapid

1. BP has well experience engineer to help your design check before machining. Our engineers have more than 10 years in CNC plastic machining field, they are also technicians previous in CNC programming, handcraft, sanding worker, CAD/UG skilled, and thus they can help to review your files with best machining process, interference check and modification, splitting patterns preparation, assembly check, and final quality approval.

2. Quick turn-around time in plastic machining. We can make your plastic prototype in 3 days and ready to ship by express to arrive in 2 days.

3. We can produce plastic parts from all types of plastic with extensive knowledge of the properties of different plastics, with lots of testing and experimentation.

4. Our team will design precision plastic components that are custom-machined to your requirements and 3D files & drawings, brass inserts installed.

Advantages of CNC Plastic Machining

Equipped with precise CNC machining equipment, our team is capable of performing many different types of machining processes to execute the best manufacturing plan for your plastic parts.

1. Plastic machining parts are in

better tolerance

CNC plastic machining offers a better precision that is not available with RTV(silicone

mold) or 3D printing. Unlike the +/0.2mm tolerance of vacuum casting parts, the

tolerance of CNC plastic parts can be +/-0.05mm or even better to +/-0.025mm

such as for bosses locations, holes and flatness.

2. CNC can make from qty 1 piece without requiring a mold

During prototype or low-volume

production, we don’t require molds with plastic machining. This process allows

the designers to create parts in 1 piece in low cost, unlike other methods. As

long as you share us the 3D file, we can CNC mill the plastic parts asap.

3. Broader Range of Materials

There are many kinds of

materials for CNC plastic machining, for example the widely use plastic ABS,

PC, PMMA, ABS+PC, PC+ABS, PP, Nylon, PA+15/30% GF, carbon fiber, POM/Derlin,

Ultem, PEEK,PVC, PEI etc, these materials can also do custom post finishing.

Why Choose CNC Plastic over 3D Printing

1. Good Strength: CNC plastic has strong strength than 3D printing, it’s a better choice for big size housings with heavy metal components inside and rough usage occasion. While 3D printing parts will get crack easily and fragile.

2. Milling details exactly same as the file: CNC plastic can mill the small details start from 0.4mm thickness in good shape and quality, the surface sketching is clear and obvious. 3d printing parts have poor surface quality and easily get broken for small structures.

Post finishing for CNC plastic machining parts

1. Paint: Matte paint, glossy paint, semi-glossy paint, texture paint, color paint(RAL/Pantone/RGB/Metallic)

2. Printing: silk screening, pad printing, laser engraving/etching.

3. Plating: silver glossy chroming, silver matte chroming, black matte/glossy chroming

4. No finish: Ra0.2~Ra3.2

If you have any CNC plastic machining projects, please feel free to contact us, we are ready to make rapid prototypes for you!

Categories

Contact Us

Contact: Kenzi Liang

Phone: 00 86 159 9963 0935

Tel: 00 86 755 2308 8415

Add: Room 401,Yan Luo Chuang Gu, YangYong Rd, SongGang BaoAn District, Shenzhen P.R.China 518127