Blog

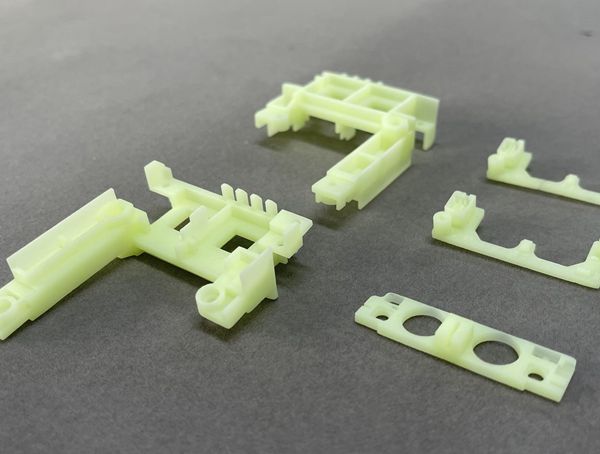

It’s not exaggerating to say 3D printing is racing into smart hardware market. As one of the most influential fairs in consumer electronics industry, 2021 CES (International Consumer Electronics Show) received nearly 30 3D printing service companies, compared with the figure 2 three years ago.

The phrase “smart hardware” refers to any intelligent devices that are transformed from old simplified prototype by adding the smart functions of hardware. Besides smart phones, the moment when we feel smart hardware can be we blow out the candle in an iPad and see the vivid fog.

To some extent, 3D printing and smart hardware have synergistic effect on each other. There are ideas that “If there was no 3D printing, wearable hardware couldn’t have made the figure as an emerging technology in 2014.” Checklight beats iWatch to win The Best Creative Award of this year. It’s an intelligent cap-like device designed for helping people do sports better. It’s currently on sale and very popular. 3D printing has contributed to its success to a very large extent. At least five printing methods have been tried in the developing process. Relying on those economical and fast rapid prototyping service, the device is finally completed after 1500 printing attempts. Another Dutch engineer also exhibited his home-printed self-defense armor.

Demand is the biggest driving force for innovation. The rule applies for 3D printing too. Because of the increasing number of industries using 3D printing, this technology is advancing quickly. The joint application of 3D printing and other technologies is making many impossible happen.

The constant achievements have broken people’s imagination boundaries. 3D printing is creating wider and wider service and industry opportunity. 3D printing, cloud computing and designing tools are turning 3D printing into a rising service industry.

While more and more old and new enterprises are flocking into 3D printing region, we must be alert to its limitations and avoid hot heads. So far, although 3D printing is becoming more and more refined and diversified into multiple fields, not a single field has formed scale. Reported applications are scattered not systematic. Moreover, materials used for printing are still rather limited. Although the price for 3D printers drop again and again, due to material reason, popularizing 3D printing still got a long way to go.

Categories

Contact Us

Contact: Kenzi Liang

Phone: 00 86 159 9963 0935

Tel: 00 86 755 2308 8415

Add: Room 401,Yan Luo Chuang Gu, YangYong Rd, SongGang BaoAn District, Shenzhen P.R.China 518127